Introduction

Acrylic boxes are made from a clear plastic called polymethyl methacrylate (PMMA). PMMA is a tough, scratch-resistant material that can be easily molded into different shapes. It is often used as an alternative to glass because it is lighter and more shatter-resistant.

Acrylic boxes are commonly used for packaging, display, and storage purposes. They can be custom-made to any size or shape and can be printed with logos or other designs.

Different Types of Acrylic

There are different types of acrylic, from acrylic plastics to acrylic sheets.

- Acrylic Plastics- Acrylic plastics are transparent, lightweight, and shatter-resistant. They can be easily molded into different shapes and are often used as an alternative to glass.

- Acrylic Sheets- Acrylic sheets are thin, transparent sheets made of plastic. They are often used for windowpanes, signs, and displays.

- Cast Acrylic- Cast acrylic is a type of acrylic plastic made by pouring acrylic acid into a mold. It is often used for making sculptures and other decorative items

- Acrylic Resin- Acrylic resin is plastic used in coatings, adhesives, and sealants. It can also serve as acrylic paint to preserve and shine acrylic boxes.

- Polymethyl Methacrylate- Polymethyl methacrylate (PMMA) is a clear plastic commonly used in acrylic boxes. It is a rigid material that can be easily molded into different shapes.

What are Acrylic Boxes?

Acrylic boxes are protective containers made from shatter-resistant transparent plastics called polymethyl methacrylate (PMMA). They are used for packaging, display, and storage purposes. Acrylic sheet is a good material for making display boxes; they can be custom-made to any size or shape and can be printed with logos or other designs.

One of the main advantages of using acrylic boxes is that they are lightweight and durable. They are also scratch-resistant and easy to mold into different shapes. In addition, acrylic boxes offer excellent clarity, making them ideal for displaying products such as jewelry and perfect for gift boxes.

Whether you need a small, medium, or large acrylic boxes to suit your needs, there is an extensive selection available on the market. You can easily find an acrylic box supplier online or in your local area.

Different Types of Acrylic Boxes

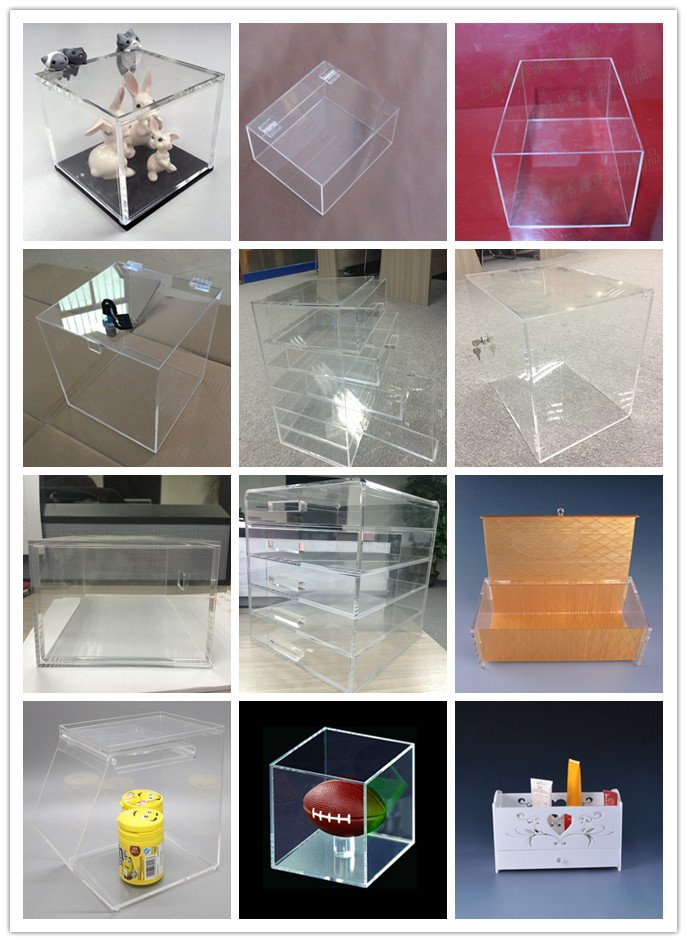

There are several different types of acrylic boxes available, including custom-made, printed, and modular acrylic boxes. Bespoke acrylic packages can be manufactured in any size or shape, making them ideal for storing or displaying various products. Printed acrylic boxes can be customized with logos or other designs to help promote your brand or uniquely showcase your products. Modular acrylic boxes are pre-assembled and come in a variety of standard sizes. They can be stacked or placed side-by-side to create a larger display.

What are Acrylic Display Boxes?

Acrylic display boxes are transparent, protective containers used to showcase products in retail settings. They are often used to display jewelry, cosmetics, electronic devices, and other small items. These boxes come in a variety of sizes and shapes. Some are made from a single piece of acrylic, while others are assembled from multiple parts.

Why Use Acrylic Display Boxes?

There are several reasons why you might choose to use an acrylic display box instead of a traditional glass or plastic box. One of the main advantages of acrylic is that it is shatter-resistant. This makes it an ideal material for displaying fragile or delicate items. In addition, acrylic is lightweight and easy to clean. It also offers excellent clarity, allowing the box’s contents to be seen from multiple angles. Whether you need a custom-made display box or a pre-assembled modular unit, there is an extensive selection available on the market. So if you are looking for a convenient and attractive way to showcase your products, consider using acrylic boxes in your next retail campaign.

Reasons Why You Should Use Acrylic Sheets For Your Display Boxes

If you plan to use display boxes for your products or services, it is essential to choose a suitable material for the package. Different materials can be used for display boxes, but one of the best options available is acrylic products. Acrylic has many advantages over other materials, making it the ideal choice for display boxes.

Some of the reasons why you should use acrylic sheets for your display boxes include:

1. Excellent Clarity

One of the main reasons why you should use acrylic sheets for your display boxes is because of the excellent clarity that it offers. This material is crystal clear, allowing your customers to see the product inside the box. This is especially important if you display delicate products like jewelry or electronics.

2. Durable and Strong

Another reason why you should use acrylic sheets for your display boxes is because of their durability and strength. Acrylic is more robust than glass or plastic, making it an excellent choice for protecting your products from damage. In addition, it is scratch-resistant, so it can withstand the wear and tear of everyday use without breaking.

3. Lightweight Material

Since acrylic is lightweight, it is easy to transport your display boxes when moving them from one place to another. This also reduces the overall shipping cost, as your packages will be easier to move and ship than heavier materials like glass or wood.

4. Cost-effective Option

Acrylic sheets are also a cost-effective option for your display boxes. Compared to other materials like glass or metal, acrylic is relatively affordable and can help you save money on your packaging costs.

Overall, if you are looking for a material that offers excellent clarity, durability, strength, and affordability, acrylic sheets make an ideal choice for your display boxes. Whether you need custom-made displays or pre-assembled modular units, there is an extensive selection of available options today. So why not choose acrylic sheets for your next retail campaign?

How are Acrylic Boxes Made?

Acrylic boxes are made from a clear plastic called polymethyl methacrylate (PMMA). PMMA is a rigid, scratch-resistant material that can be easily molded into different shapes. It is often used as an alternative to glass because it is lighter and more shatter-resistant.

To make an acrylic box, manufacturers start with large sheets of PMMA. These sheets are then cut to size and shape using a computer-controlled cutting machine. Once the pieces have been cut, they are placed into a mold and heated until they soften. The softened elements are then formed into the desired shape and cooled.

After the acrylic box has been formed, it is typically sanded and polished to remove any surface imperfections. The finished product can then be printed with logos or other designs if desired.

Whether you need a small, medium, or large acrylic box for your needs, many options are available on the market. You can easily find an acrylic box supplier online or in your local area that offers high-quality products at competitive prices. With so many benefits and features, it is no wonder that acrylic boxes are one of the most popular packaging solutions today.

Process of Producing Acrylic Boxes

Acrylic boxes are made from a clear plastic called polymethyl methacrylate (PMMA). PMMA is a rigid, scratch-resistant material that can be easily molded into different shapes. It is often used as an alternative to glass because it is lighter and more shatter-resistant.

Purchase Material

To produce acrylic boxes, the first step is to purchase large sheets of PMMA. This material can be obtained from various sources, such as specialty plastics suppliers or online retailers.

Cutting of the Material

Once the material has been obtained, it needs to be cut into smaller pieces. This is typically done with a computer-controlled cutting machine. The size and shape of the details will depend on the desired final product.

Trimming/bevel edges

After the pieces have been cut, they need to be trimmed or beveled to give them a smooth, uniform appearance. This is typically done using solvent cement to remove the waste plastic where the solvent tape was placed.

Polishing

Once the pieces have been trimmed and shaped, they need to be polished to remove surface imperfections. However, you need to remove the solvent-proof tape placed on the four edges of the box before polishing. This is typically done using sandpaper or other polishing tools such as wet sand.

Printing/Decorating

The final step is to print or decorate the acrylic boxes with logos or other designs if desired.

Bonding

After the printing and decorating process is complete, the pieces need to be bonded together. This can be done using various methods, such as welding, adhesives, or fasteners.

Packaging

Once the bonding process is complete, the acrylic boxes must be packaged for shipping. This typically involves placing them in protective packagings, such as bubble wrap or foam.

Benefits of Acrylic Boxes

There are many benefits to using acrylic boxes for packaging, storage, and display. Some of these benefits include:

· They are durable and long-lasting.

Acrylic Boxes are durable due to their scratch and shatter-resistant properties. This makes them ideal for packaging products that need to be shipped or stored for long periods.

· They are easy to clean and maintain.

Acrylic boxes are easy to keep clean and free of dust and dirt. Wipe them down with a damp cloth when needed.

· They are crystal clear.

Acrylic boxes provide excellent clarity, which is perfect for displaying products. Customers can easily see what is inside the box without opening it up.

· They are lightweight.

Acrylic boxes are much lighter than glass or other types of packaging materials. This makes them easier to transport and helps reduce shipping costs.

· They are recyclable.

Acrylic boxes can be recycled at the end of their lifespan. This makes them an environmentally-friendly packaging option.

Conclusion

Acrylic boxes are a popular packaging solution for many businesses due to their numerous benefits and features. If you are looking for an attractive, durable, and eco-friendly packaging option, then consider using acrylic boxes for your next project.