The application of acrylic boxes is very wide, in the process of using acrylic boxes often involve the lid, because the lid determines the use of the box function. Then at the beginning of the design of acrylic boxes need to consider the lid.Because the lid will affect the use of acrylic box function.

1, the flat hinge lid

The hinge lid is a hinge to the acrylic box hinge and lid together as one. The hinge flap is the most commonly used design method. It is also the most solid acrylic box lid.

Hinge is divided into plastic and metal material

Among the plastic material and acrylic transparent hinges are most commonly used, but also white, black, etc. If the order quantity is large, then we can customize according to the required color.

Generally transparent color boxes use transparent hinges, white boxes use white corresponding hinges, black is also the use of black hinges, so that the whole box looks beautiful.

The use of such hinges need to pay attention to, when turning the hinge and the box bonding place can not appear sound, which requires the factory workers in the bonding time special attention.

The bonding should also be careful, it must be firm to avoid falling off.

2, the lid of the plug tip

This is also a kind of hinge lid, but is connected to the box and the lid by a short tip

(1) Small pins made of metal, very short.

This small one is low cost for production

(2) Long plug tip lid

Such a lid is also a flip lid, with a long metal tip, very long. Such a lid structure is rarely used.

3, Sink the lid, put it down directly.

This type of lid is to use CNC machine to mill the lid around the groove into the shape of a step, so that you can directly fit the lid just into the box, so that the lid is very good into. Such lids often need a puller on top of the lid in order to easily pick up and put into the box.

4, the five-sided lid

Such a lid like a hat, you need to manually heat bend and splice a small five-sided box as a lid, and then the size is just right to fit into the box.

5, The lid of the hexagon

Correspondingly means that the sides have six sides, these types of lids are often manually spliced together. Production of this type of lid is a little more difficult than other types of lids, often not used much, this type of lid general food boxes, jewelry storage boxes with more.

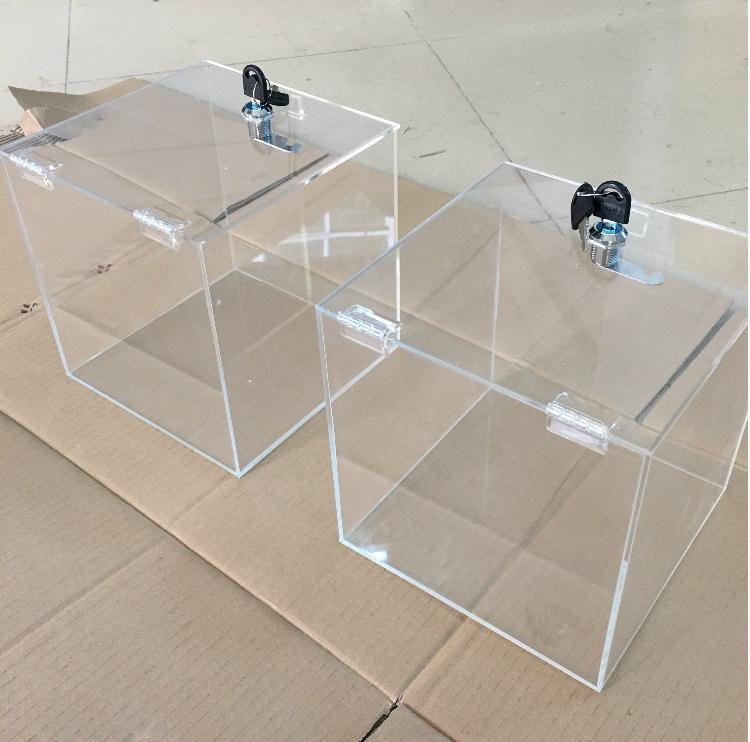

6, Snap-on lids

This type of cover has a relatively simple structure.

Often need a snap or lock or something as an aid to play a role, such as donation boxes and ballot boxes, etc., generally need a lock to assist in order to play a role in sealing security.

7, Sliding lid

Need to cut slots on both sides of the box, so that the lid can move well between the slots – open and close

8, the other lids

Other lid types such as round ones, which are often used more for flower boxes.

In short, the function and use of the box needs to be combined to make the optimal choice of lid type. It needs the designer to use enough imagination to accomplish it.